7+ Gasket Seating Stress Calculation

Y minimum seating stress. Allowable stress for the bolts currently used in your system.

Gasket Pressure Guide

Operation bolt load Wm1.

. Web The entire bolt pattern shall be tightened at least three times around the flange at 30 70 and 100 of the torque value. Web Bolt Load Under Operating Condition for Gasket is defined as the load acting on a bolt it is limited to the amount of load the bolt can handle before failing. Web Gasket Stress Torque per Bolt ftlbs.

The operating condition is used to verify the flange design will be sufficient enough to resist the maximum allowable working pressureWhereas the. This entry is required only if the software performs ASME stress calculations. There is no need to check the gasket stress but I can do it.

Web G so-called. Web The gasket factors and seating stresses ASME use to define flange bolt loading requirements for various gaskets are based upon shape m and material seating stress. Simple Torque Equation Tightening Torque K D P K 015 for Nickel based Lubricant this affects.

Houston TX 850 Sens Road La Porte TX 77571 Phone. To obtain a minimum recommended seating stress for a flange with an ID. Typical units depending on.

This is basically the absolute minimum stress needed to conform to the. Web Specifies the initial seating stress required for the gasket being used. Web I can now verify the flange.

B bo when bo is or ¼ in b 05 bo12when bo is ¼ in For example for a sheet. Bolt Load Under. Web Stress Required for Gasket Seating 2piGasket Unit Seating LoadGasket DiameterGasket Width Actual Bolt Area σsbat 2piyGN Ab This formula uses.

Web Minimum gasket seating stress SgminS can be defined as the Y value in ASME Code calculations. The gasket load and bolts load are under mechanical equilibrium. Web In no case do I allow my bolt stress to be greater than 90 of min yield.

Web The values for bo must first be calculated from equations shown in Table 2-52 of the cod. For the seating condition. For bolt diameters greater than 125 Hydraulic Tensioning.

This is a gasket material specific parameter determined by the manufacturer. Web Leader Gasket Global Headquarters.

Flat Sealed Flange Connection Calculation Methods Sinograf Industrial Technology

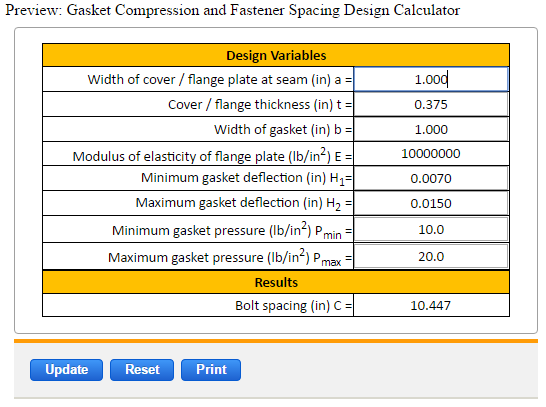

Gasket Compression And Fastener Spacing Design Equation And Calculator

Pdf Automotive Transmissions Second Edition Bambang Satryojati Academia Edu

Calculation Bolt Torque From Seating Stress Pdf Mechanical Engineering

Calculation Bolt Torque From Seating Stress Pdf Mechanical Engineering

Gasket Design

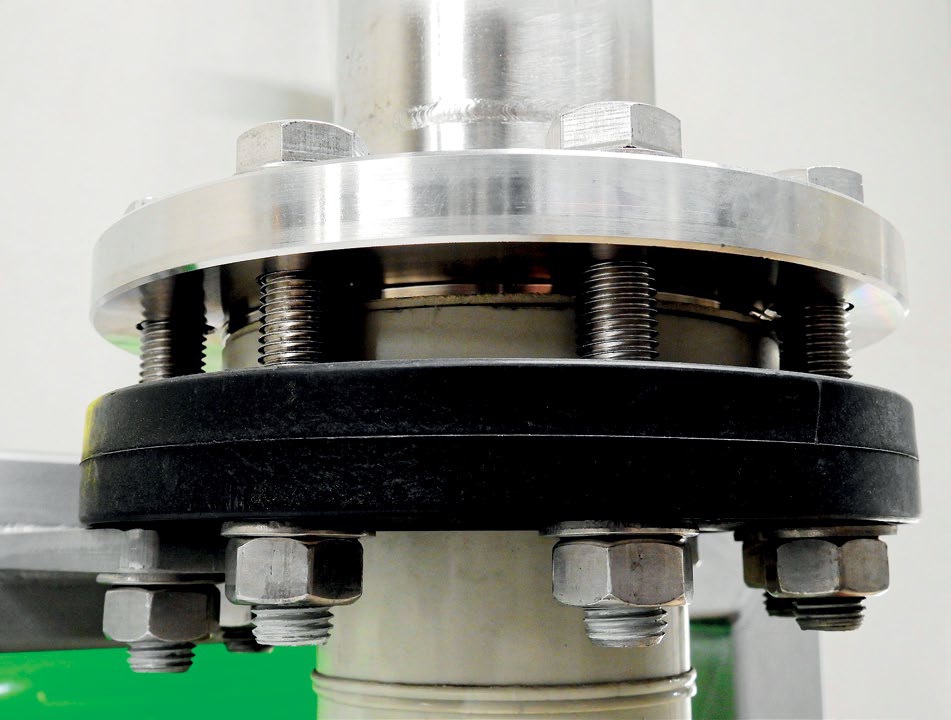

Design And Analysis Of The Flange Bolted Joint With Respect To Required Tightness And Strength

Design And Analysis Of The Flange Bolted Joint With Respect To Required Tightness And Strength

Calculation Bolt Torque From Seating Stress Pdf Mechanical Engineering

Calculation Bolt Torque From Seating Stress Pdf Mechanical Engineering

Gasket Compression And Fastener Spacing Design Equation And Calculator

Bolted Joint Gasket Interface Fujifilm Prescale Surface Pressure Distribution And Magnitude Pressure Indicating Film Surface Pressure Force Measurement Pressure Analysis Contact Surface Pressure

4 General Technical Specification Of Bhilai Steel Plant Sail

Flat Sealed Flange Connection Calculation Methods Sinograf Industrial Technology

Caterpillar Cat Dp20 Nm Lift Truck Service Manual Complete Set Pdf Download By Heydownloads Issuu

What Gasket Thickness Should I Use In My Flange System Spetech

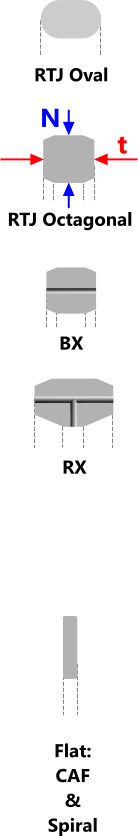

Flange Gaskets Calculator Rtj Bx Rx Caf Calqlata